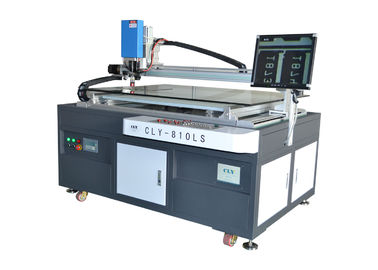

CLY-810LS Laser Repair Machine for LCD Screen Repair Bonding Machine

Product Description

Imaging system

Computer System Frame Computer, Image AcquisitionCard and Display Card

Display 15 inch LCD displayCamera SXT 403 DC12V

Amplification rate 400, 800, 1600 times

Light source adjustable, coaxial light source and spotlight source and LED backlight module

Mount base confidential steel base

X, Y effective stroke 1250 mm X 900 mm

X, Y axis drive form with servo motor system confidential screw

X, Y minimum resolution of 1 um/pulse

Less than or equal to 5 um reproducibility

Z axis range of 100 mm

The Z axis driver form with servo motor system confidential screw

The Z axis minimum resolution 0.1 um/pulse

Will be subject to the actual design configuration.

Equipment parameters

| Type |

LCD screen Laser repairing machine |

| Power supply |

voltage 220V |

| Exterior size |

2320 mm * 2160 mm * 2000 mm (the actual design shall prevail) |

| Machine weight |

1200kg |

| Working environment temperature |

20 ºC~30 ºC + / - 5 ºC |

| Work environment relative humidity |

65 + / - 5% RH |

| Laser system |

VD control system |

| LASER types |

ND YAG LASER |

| Wave length |

1064/532 nm double wavelength (532 nm for adjust the optical wavelength) |

| cooling method |

Water-cooled/air-cooled |

| laser power |

3-8 mj/Pulse |

| Vibration frequency |

1 ~ 20 Hz/seconds |

| The maximum peak power |

1mW |

| 1064 wave amplitude |

8 ~ 6 nsec |

| Output power control |

512 steps for 0-100% Hi/Low switch - able |

| Flash Lamp Life Time |

1year or greater than 1000000 shots |

| Laser oscillator warranty period |

1 year |

| Interface |

RS - 232 |

| Other name |

Laser machine |

| The actual laser configuration specifications shall prevail |

For maximum 65 inch LCD panel screen size.

Point (3 um X 3 um), line (50 um long X 3 um), block (50 um X 50 um) repair

To repair the mist of polarizing film containing the LCD panel

Dual display electronic brake light red and red box

Light gate size and the parameters of the lens ratio and laser power storage and use

Working power supply: 220 v, 30 a

Repairing Type

Laser machine, the purpose of repair is further hope to be able to correct the defective part, make originally filtered to throw away waste products, to patch the acceptable products. At the current acceptable product standards, the first is absolutely no color line defect; Second, at present many products have highlight the "no spot guarantees", therefore cannot have a pixel is always shine bright spot, but it can be a way to accept a few dark spots. So the object of laser repairing, mainly on color line defect and bright spot.

The laser repairing ways

Welding: in a second metal overlapping across, use the appropriate energy and wavelength of laser, melt the metal parts and welding together, connecting the two electrode which was not connected (and to realize disconnection by cut off ) to realize repairing.

Main usage

LCD screen laser repair machine (hereinafter referred to as laser machine), in the LCD screen maintenance industry is at high-end technology of repairing, is the most high-end technology. In the LCD screen repair area except COF losing welding, TAB burnt (the fault with can be repaired by bonding machine) other such as bright line, half line, point, line, coarse, multi-line can use laser machine to repair. Laser machine in the LCD screen repair process has high efficiency, high repair rate, low cost (the same fault in the laser machine does not need to replace parts, not only save cost but also improve repair rate not influenced by lack accessories) etc, and widely used by large production factory, brand after-sales and maintenance of the company as a main screen equipment.

Processing load and X/Y/Z axis driving system

Size 1250 mm X 900 mm work platform

Load material precision grinding optical glass platform.

Optical imaging system

Microscope: observation/laser processing and special

The CCD: 1/2 "color CCD

Fall shoot the light source, high brightness halogen light source system: (100 w)

Transmission light source, high brightness halogen light source system: (150 w)

Guide Light high brightness halogen Light source system: (100 w)

Objective switching system: 4 hole/electric switch mode (linear)

Precision optical lens group: 5x, 10x, 20x, 50x (the latter two have observed/laser processing function).

About us

Guangzhou Chuangliyou Machinery Equipment Co., Ltd.

Guangzhou Chuangliyou Machinery Equipment Co., Ltd. is located in Dashi, Panyu District, Guangzhou City, where is a prosperous commercial city. It is located in the central area of Dashi Industry, adjacent to the most perfect LCD electronic procurement and wholesale market in China. Guangzhou Chuangliyou Machinery Equipment Co., Ltd. is specialized in the research and development, design, production and sales of various pneumatic hot press equipment. Large-scale enterprises as a whole.

FAQ

1. Can you do OEM?

Yes. Also can be customized according to the customer's specific requirements.

2. If 110V is available?

Yes. 110V and 220V can be switched arbitrarily.

3. What kind of plug does your product equip with?

American or Australian or European or UK plug or other types of plug.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!